The Biggest Ready-Mix Concrete Projects In The World – Ranked

Concrete is the backbone of modern construction, used in structures from towering skyscrapers to sprawling dams.

Ready-mix concrete, a specialized form of concrete delivered fresh to construction sites, has transformed how these massive structures are built. With precise mixing, ease of delivery, and uniform quality, it’s trusted globally for projects that require strength, durability, and precision.

In this blog, we’ll explore the largest ready-mix concrete projects ever undertaken, showcasing just how reliable and versatile this material is.

Enjoy this impressive list of record-breaking projects that prove the power of ready-mix concrete!

10. Itaipu Dam, Brazil/Paraguay

-Amount of Ready-Mix Concrete Used: Over 12.3 million cubic meters

-Completed: 1984

Generating over 14,000 MW of hydroelectric power, the Itaipu Dam is one of the largest dams in the world.

This bi-national project required substantial volumes of ready-mix concrete to construct its vast retaining walls and spillways.

Itaipu is a prime example of how ready-mix concrete can handle both the scale and environmental demands of large hydroelectric projects.

9. Gotthard Base Tunnel, Switzerland

– Amount of Ready-Mix Concrete Used: Around 4 million cubic meters

-Completed: 2016

The world’s longest railway and deepest traffic tunnel stretches 57.1 kilometres beneath the Swiss Alps.

Ready-mix concrete was chosen because it could endure the extreme pressures and temperatures found deep underground. Proof of the material’s capacity for complex, subterranean projects.

8. Petronas Towers, Malaysia

-Amount of Ready-Mix Concrete Used: Estimated 160,000 cubic meters

-Completed: 1998

The Petronas Towers, once the tallest twin towers in the world, relied on ready-mix concrete to achieve a durable and earthquake-resistant structure.

The towers soar to 452 meters and required the pouring of massive, reinforced foundations; another testament to ready-mix concrete’s essential role in high-rise architecture.

7. Channel Tunnel, England/France

-Amount of Ready-Mix Concrete Used: Over 3 million cubic meters

-Completed: 1994

The Channel Tunnel, a 50.5 km underwater railway connecting the UK and France, was one of the most ambitious projects of its time.

Ready-mix concrete was used extensively in creating the tunnel’s sections, needing to withstand the marine environment and structural pressures deep underground.

The tunnel highlights how ready-mix concrete can perform under extreme conditions.

6. The Pentagon, USA

-Amount of Ready-Mix Concrete Used: Approx. 435,000 cubic meters

-Completed: 1943

Constructed during World War II, the Pentagon remains the world’s largest office building.

Its layout required substantial ready-mix concrete to form its five-ring design, providing structural stability and resilience.

The speed of construction was critical, so ready-mix concrete came to the rescue and proved its value in time-sensitive, large-scale projects.

5. Hoover Dam Bypass, USA

-Amount of Ready-Mix Concrete Used: Around 200,000 cubic meters

-Completed: 2010

The Hoover Dam Bypass, also known as the Mike O’Callaghan – Pat Tillman Memorial Bridge, required massive amounts of ready-mix concrete for its construction.

It spans the Colorado River; providing a crucial transport link and showcasing how ready-mix concrete can be effectively used in challenging terrain and for structures requiring high load-bearing capacity.

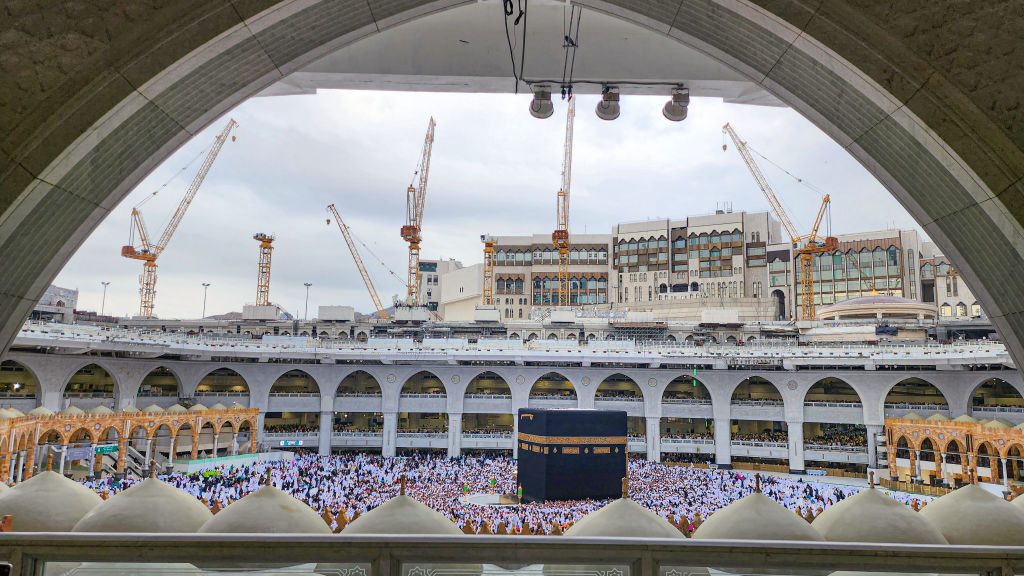

4. The Grand Mosque, Saudi Arabia

-Amount of Ready-Mix Concrete Used: Estimated 3 million cubic meters

-Completed: Ongoing (multiple phases)

The Grand Mosque, one of the world’s largest religious sites, has undergone numerous expansions over the years, each involving extensive use of ready-mix concrete.

With over a million pilgrims visiting annually, structural resilience and quality were paramount.

Ready-mix concrete was chosen for its ability to meet both the structural demands and aesthetic requirements of this globally significant landmark.

3. Panama Canal Expansion, Panama

-Amount of Ready-Mix Concrete Used: Over 4.5 million cubic meters

-Completed: 2016

The expansion of the Panama Canal, a key trade route essential to global commerce., required extensive concrete work to build new locks capable of accommodating larger ships.

This project used specially formulated ready-mix concrete to ensure resistance against water and the elements, highlighting its effectiveness in marine construction.

2. Burj Khalifa, Dubai

-Amount of Ready-Mix Concrete Used: Approximately 330,000 cubic meters

-Completed: 2010

Burj Khalifa, the world’s tallest building (828 meters high) is a marvel of engineering that relied heavily on high-strength ready-mix concrete.

That the concrete was specially mixed to withstand Dubai’s high temperatures highlights the adaptability of ready-mix concrete in demanding environments. The material was also pumped to record-breaking heights, showcasing its capability for skyscraper construction.

1. Three Gorges Dam, China

-Amount of Ready-Mix Concrete Used: Estimated 16 million cubic meters

-Completed: 2012

As the world’s largest hydropower project, the Three Gorges Dam on China’s Yangtze River used a staggering amount of concrete.

Ready-mix concrete was crucial to creating this colossal structure that measures over 2,335 meters in length and 185 meters in height.

The dam’s structural integrity relies heavily on ready-mix concrete’s ability to withstand massive water pressure and deliver long-term durability.

Why Ready-Mix Concrete is Ideal for Mega Projects

These record-setting projects demonstrate the strength and versatility of ready-mix concrete. For massive undertakings requiring precise formulations, durability, and efficient delivery, ready-mix concrete is indispensable.

The benefits of using ready-mix concrete in such projects include:

- Precision in Mixture: Each batch is mixed with exact proportions, ensuring consistency in strength and quality.

- Efficient Delivery: Ready-mix concrete is delivered in batches to fit the construction schedule, reducing onsite labour and waste.

- Adaptability: Customizable mixes can be created for specific project needs, from marine structures to skyscrapers and tunnels.

- . Durability and Strength: With formulations that can withstand harsh environments, ready-mix concrete is ideal for projects requiring longevity and resistance to weather, water, and pressure.

Novum Concrete: Your Trusted Partner for Mega Projects in Kenya

At Novum Concrete, we understand the demands of large-scale construction projects. With our advanced mixing facilities, robust delivery fleet, and commitment to quality, we are well-equipped to supply any project, regardless of size.

Whether building infrastructure, high-rises, or commercial spaces, we can meet your requirements with precision, efficiency, and reliability.

Our commitment to quality ensures that your project, big or small, is built on a foundation that will last.

If these global projects have proven anything, it’s that ready-mix concrete, provided by a trusted partner like Novum Concrete, can be trusted to handle the weight, scale, and challenge of even the most ambitious constructions.